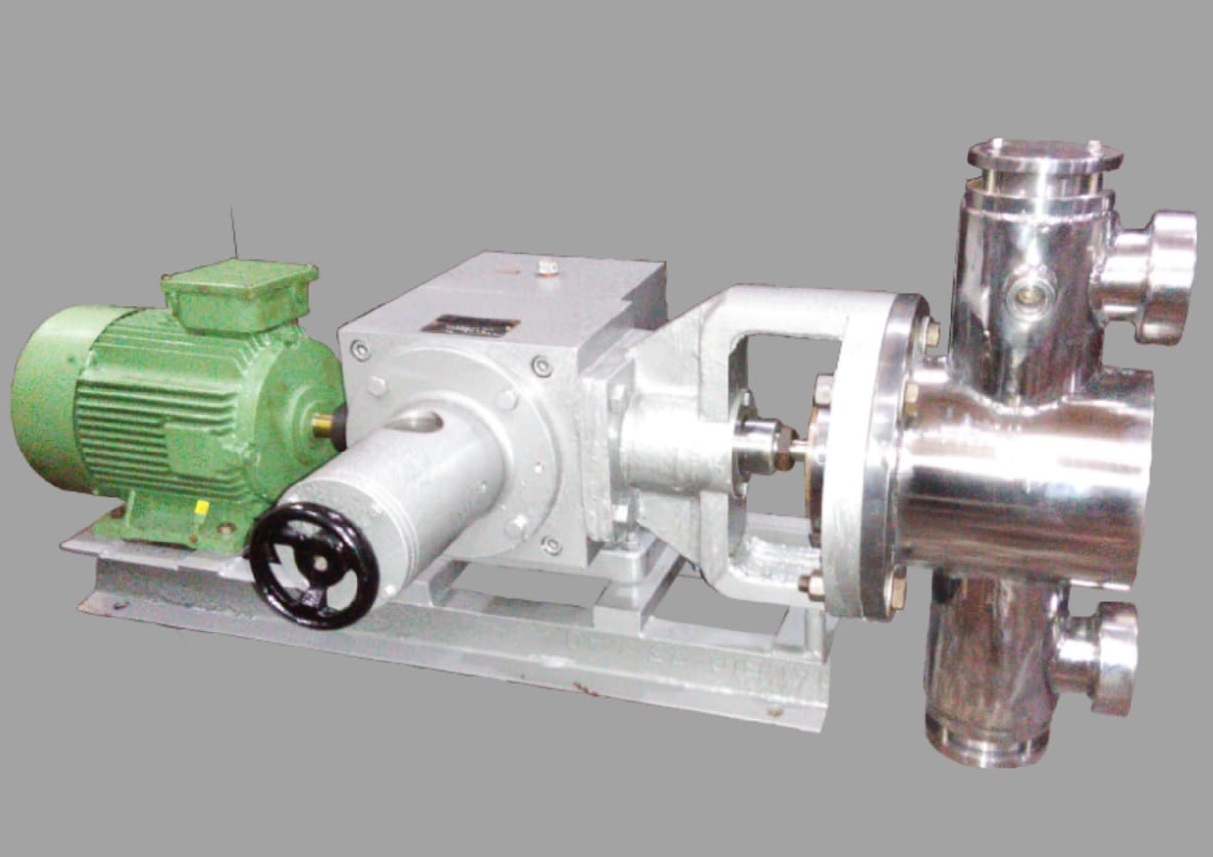

Steam Jacketed Metering Pump Manufacturer in Mumbai India

The world class manufacturer and exporters of Gear Pump known for their reliable service and international standard products. Gear Pump is being widely used in the chemical plants and at all the other places where the viscous and semi-liquids are utilized. The pump is in high demand because of its tough and seamless finishing, good suction quality and deliberation capacity. The superior quality Rotary Gear Pump is available in the market with unique features and special design features at leading market price. An inner part of the Rotary Gear Pump is a positive displacement that operates a rotor and idler gear assembly for generating it flow. The assemblage is counteracted, with a crescent adjoining to the inner gear all along with the out gear. As the rotor gear drives the idler gear the space causing the bow-shaped offsetting the gears that mesh the gear teeth displacing and expelling it to the discharge. Oils, bitumen, fats, syrups, cocoa, and resins are often specified for internal rotary gear pumps because the more viscous the substance is, the more efficient the displacement part of the working principle becomes. Fluids can be handled using an internal rotary gear pump.Because the gear mechanism is finished with fine tolerances, a gear pump has several advantages in terms of suction and discharge performance. It excels at handling viscous substances such as chocolate, fats, oils, and similar because to the nature of the gear teeth and the powerful action. Although the pump can handle particles and abrasive material well, the cumulative, smooth delivery of the gear teeth meshing allows the pump to manage shear-sensitive fluids with a soft non-pulsating flow. The flow is directly proportionate to the speed, regardless of pressure, allowing the service operator far more control and reliability. MOC cast iron, SS316, c.s .wax and molted sulfur transfer use on steam jacketed pump also.,

Get A Quick Call!

Get A Quick Call!